Total Frequency Control News ....

Direct heating of QCM elements - June 2013

The use of thickness shear mode quartz crystals for mass sensing is a widely used technology in biological and industrial applications. The AT cut quartz crystal is the most widely used for its low cost, sensitivity, good signal to noise ratio and stability at ambient temperatures. For higher temperature operation, IT cut and SC cut crystals are a good design option for QCMelements as they have more manageable frequency / temperature characteristics at temperatures in the ranges higher than +100C.

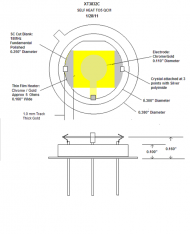

Laptech Precision manufactures these three types of element in both fundamental and overtone modes. In addition to this we have developed techniques for reaching elevated temperatures with Integrated Heating Electrodes. This capability is achieved by using thin film heaters deposited on the QCM element directly, providing there is enough room on the QCM to do so.

In cases where there is insufficient room for fully isolated heaters, the heating element can comprise of one of the main electrodes operating with a DC bias voltage. This can be used to rapidly heat up the QCM for thermal stability reasons or to provide a high temperature degas or cleaning effect. One of the challenges with direct heating is the need to sense the temperature of the quartz surface and controlling that temperature effectively. Miniature chip thermistors can be used and thermocouples can be integrated but both these options add cost and complexity.

The following article written by Gordon Hayward and Steve Baksa appears in the Royal Society of Chemistry library and describes an elegant method of thermal control using the change in electrode resistance with temperature.

http://pubs.rsc.org/en/content/articlelanding/2013/ay/c3ay26250b#!divAbstract

A hybrid sensor designed and manufactured by LapTech Precision for this purpose, consisted of a directly heated 18MHz fundamental mode SC QCM mounted on an HC35/U crystal base. The sensor in question was used successfully to detect the gas nickel carbonyl at levels as low as 6 parts per billion. The technique may also have many other applications such as high temperature thin film thickness monitoring. This heating approach has the potential to operate the sensor above the maximum process temperature eliminating the need for water cooling. Any QCM application that requires a degas cycle or rapid warm up with low power consumption could potentially benefit from direct heating technology.

Please send any enquiries to sales@tfc.co.uk

Other News Items

NEWS

TFC’s high quality, miniature ceramic smd, crystal clock oscillator manufactured over the wide ... more

TFC’s comprehensive range of SMD power inductors have an inductance value from 1uH to 1500uH ... more